Documentation: Project 03

Project 03:

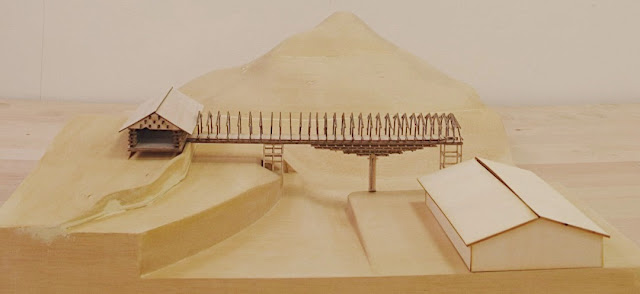

Yusuhara Wooden Bridge Museum (Structure)

Scale: 1:25

Dimension: 422 x 340 x 313 mm

Material: Poplar Plywood 6 mm / Beech Plywood 1.5 mm / Sand Papers / Timber Glue

Technique: Laser Cut

Time to Finish: 18 hrs (Digital Model: 6 hrs / Laser Cut: 2 hrs / Assembly: 10 hrs

Cost: $120 (Laser Cut Materials: $90 / Laser Cut: $60)

Digital Model

Process

Laser Cut File

2 Poplar Plywood (600 x 1200 mm) & 1 Beech Plywood (400 x 600 mm)

Assembly

Compared with the model 'Project 02'

Reflection

The process of making this model allows me to have a better understanding of the ways that timber structure is joined. However, the physical model cannot meet the previous objective without applying any adhesive. Although the digital model is designed to have gaps and holes allowing columns to be joined (which is the same approach as the original structural design from research and study), but due to the consequence of sanding the timber surface, the columns become thinner and not able to be stable when these components are assembled together. Therefore adhesive is applied to ensure the model is stable. In addition, the experience of cutting thick laser cut panels (6 mm plywood) allow me to realise that it required a much longer time than thinner one (one panel require to be cut approximately 50 mins).

Yusuhara Wooden Bridge Museum (Structure)

Scale: 1:25

Dimension: 422 x 340 x 313 mm

Material: Poplar Plywood 6 mm / Beech Plywood 1.5 mm / Sand Papers / Timber Glue

Technique: Laser Cut

Time to Finish: 18 hrs (Digital Model: 6 hrs / Laser Cut: 2 hrs / Assembly: 10 hrs

Cost: $120 (Laser Cut Materials: $90 / Laser Cut: $60)

Digital Model

Process

Laser Cut File

2 Poplar Plywood (600 x 1200 mm) & 1 Beech Plywood (400 x 600 mm)

Assembly

Although there have holes in each column allows for joining, but due to the influence of sanding (the materials become thinner), the model is not able to be stable. Therefore adhesive (Timber glue) is applied on the model.

Due to the size and characteristic of the plywood, the flooring pieces are not flat. Therefore masking tapes and adhesive is applied to ensure the panels become flat.

Compared with the model 'Project 02'

Reflection

The process of making this model allows me to have a better understanding of the ways that timber structure is joined. However, the physical model cannot meet the previous objective without applying any adhesive. Although the digital model is designed to have gaps and holes allowing columns to be joined (which is the same approach as the original structural design from research and study), but due to the consequence of sanding the timber surface, the columns become thinner and not able to be stable when these components are assembled together. Therefore adhesive is applied to ensure the model is stable. In addition, the experience of cutting thick laser cut panels (6 mm plywood) allow me to realise that it required a much longer time than thinner one (one panel require to be cut approximately 50 mins).

评论

发表评论