Documentation: Project 02

Project 02:

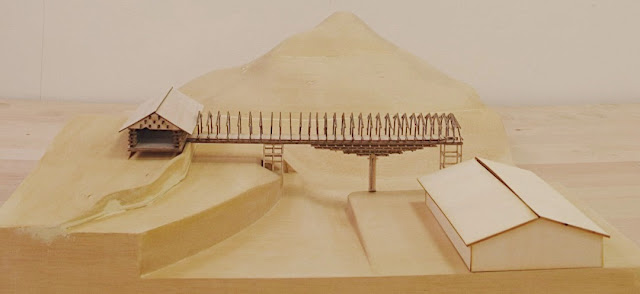

Yusuhara Wooden Bridge Museum

Scale: 1:200

Dimension: 450 x 450 mm

Material: Jelutong Timber Block / Eucalyptus Plywood (1.5 mm) / Basswood Plywood (1.5 mm) / Timber Glue / Sand Papers / Wood Filler / Clear Polyurethane

Technique: CNC / Laser Cut

Time to Finish: 50 hrs (Digital Model: 15 hrs / CNC Cut: 3 hrs / Laser Cut: 2 hrs / Assembly: 30 hrs)

Cost: $444 (Jelutong Timber: $133 / Laser Cut Materials: $60 / CNC: $150 / Laser Cut: $60 / Sand Papers: $10 / Timber Glue: $7 / Wood Filler: $10 / Clear Polyurethane: $14)

Digital Model

Process

There are 11 components been built in different layers during the process.

CNC File:

2 Panels (500 x 500 x 58 mm Jejutong Timber Block)

Laser Cut File:

Two panels in 400 x 600 mm size (Eucalyptus / Basswood Plywood 1.5 mm)

0.6 mm strips connecting each column avoid the pieces to drop separately on the base of the laser cut machine.

Machine/Technique Applied/Assembly

Timber Workshop / CNC

The surface of timber blocks that have been purchased (300 x 1000 x 60 mm & 300 x 550 mm)are very rough and does not meet the correct height to be cut. Therefore the machine is used to cut the timber thinner to 58 mm (1 mm each time). This process is helped by the staff work in the timber workshop.

Dimensions have been correctly cut into 250 x 500 mm.

Holes are cut through timber to put the joining pieces into the blocks in order to join two timber blocks more stable (500 x 500mm).

Since there has different cutting height (Mountains VS flat ground) process by CNC machine, therefore the joints are placed into different height.

CNC Machine processing

Remove the excess pieces and sand roughly.

Connect pieces together.

Remove the cutting trace from CNC by sanding the surface and use wet towel to clean.

After it is dry (approx. 12 hrs), sand until smooth and use a wet towel to clean the surface again. It also allows to test the colours after polish.

After assembled all the components together, it has been placed on the base site model.

Reflection

This model allows me to experience a variety of new techniques (CNC&Timber workshop) during the making process. Meanwhile, the challenge has been faced during joining each small columns and components together and be stable. This may consider as because the dimension of the main building is too small to achieve the details of the design appearance, however, it is appropriate for the site model since it will be too large if increase the scale of the entire project. In addition, thin timber strips are found useful when to apply glue on a small surface.

Yusuhara Wooden Bridge Museum

Scale: 1:200

Dimension: 450 x 450 mm

Material: Jelutong Timber Block / Eucalyptus Plywood (1.5 mm) / Basswood Plywood (1.5 mm) / Timber Glue / Sand Papers / Wood Filler / Clear Polyurethane

Technique: CNC / Laser Cut

Time to Finish: 50 hrs (Digital Model: 15 hrs / CNC Cut: 3 hrs / Laser Cut: 2 hrs / Assembly: 30 hrs)

Cost: $444 (Jelutong Timber: $133 / Laser Cut Materials: $60 / CNC: $150 / Laser Cut: $60 / Sand Papers: $10 / Timber Glue: $7 / Wood Filler: $10 / Clear Polyurethane: $14)

Digital Model

Process

There are 11 components been built in different layers during the process.

CNC File:

2 Panels (500 x 500 x 58 mm Jejutong Timber Block)

Laser Cut File:

Two panels in 400 x 600 mm size (Eucalyptus / Basswood Plywood 1.5 mm)

0.6 mm strips connecting each column avoid the pieces to drop separately on the base of the laser cut machine.

Machine/Technique Applied/Assembly

Timber Workshop / CNC

The surface of timber blocks that have been purchased (300 x 1000 x 60 mm & 300 x 550 mm)are very rough and does not meet the correct height to be cut. Therefore the machine is used to cut the timber thinner to 58 mm (1 mm each time). This process is helped by the staff work in the timber workshop.

Dimensions have been correctly cut into 250 x 500 mm.

Holes are cut through timber to put the joining pieces into the blocks in order to join two timber blocks more stable (500 x 500mm).

Since there has different cutting height (Mountains VS flat ground) process by CNC machine, therefore the joints are placed into different height.

CNC Machine processing

Connect pieces together.

Remove the cutting trace from CNC by sanding the surface and use wet towel to clean.

Apply wood filler to fill the holes and burnt trace on the timber surface.

After it is dry (approx. 12 hrs), sand until smooth and use a wet towel to clean the surface again. It also allows to test the colours after polish.

Clear polyurethane has been applied for two layers.

Laser Cut

Small joining sticks are removed due to the consideration of size and effect.

After assembled all the components together, it has been placed on the base site model.

This model allows me to experience a variety of new techniques (CNC&Timber workshop) during the making process. Meanwhile, the challenge has been faced during joining each small columns and components together and be stable. This may consider as because the dimension of the main building is too small to achieve the details of the design appearance, however, it is appropriate for the site model since it will be too large if increase the scale of the entire project. In addition, thin timber strips are found useful when to apply glue on a small surface.

评论

发表评论